Our Range of Drain Manhole Covers and Frames

Our manhole covers and frames are available in different materials and are compliant with industry standards. Our vast selection means you can choose the drain manhole cover that best suits your needs.

We do an in-house material take off service from drawings supplied by the customer to provide an accurate estimate of goods; this way customers don’t risk overpaying. We perform this quotation service in-house to save time and money and offer it as a free-of-charge service with no obligation.

Along with our free quotation service, we provide next-day delivery on orders placed by 4 pm. This service is based on location, but you can still benefit from free delivery on orders over £100.

Why Choose Drainfast?

- Over 20 years of experience

- Expert support

- Free material take-offs

- Next-day delivery

- BS EN 124 compliant manhole covers

Manhole Covers and Frames FAQs

What Is A Manhole Cover and Frame?

A manhole cover is a removable lid that covers sewers and underground drainage systems. It is designed to be large enough for maintenance personnel to enter and robust enough to support heavy loads from automobiles. The frame is the fixed outer structure on which the manhole cover sits and is typically made from concrete and asphalt. It serves as a stable, load-bearing base for the cover and ensures a flush, secure fit. A properly fitted frame is essential for safety and surface integrity. It also helps prevent debris, water and dirt from entering the system.

What Are The Different Materials Used For Manhole Covers?

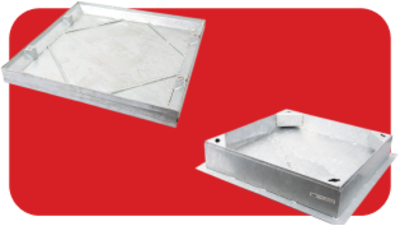

Galvanised Steel Manhole Covers

Key Features:

- High corrosion resistance

- Lightweight for easy handling and installation

- Durable for long-term outdoor use

Benefits:

Our galvanised steel manhole covers are an ideal solution for outdoor areas prone to weather exposure. They provide excellent resistance to rust and corrosion, ensuring long-lasting durability. These covers are lightweight yet robust, making installation and removal quick and straightforward. Their non-slip surface enhances safety, especially in pedestrian areas or places with high foot traffic.

Applications:

- Driveways and gardens

- Light commercial sites

- Pedestrian areas

Polypropylene Manhole Covers

Key Features:

- Lightweight and corrosion-resistant

- Resistant to chemicals and weather

- Simple installation

Benefits:

Our plastic manhole covers offer a lightweight yet durable solution, particularly in areas where chemical resistance is important. These covers are easy to install and handle, making them suitable for quick installations or temporary solutions. Polypropylene makes a great option for manhole cover squares in landscaped areas that are exposed to frequent moisture. Their resistance to corrosion ensures they perform well in wet or chemically exposed environments.

Applications:

- Gardens and pedestrian walkways

- Chemical plants

- Temporary drainage installations

Which Manhole Covers Are Best?

Manhole covers and frames are made of ductile iron, galvanised steel or polypropylene. They come in a range of sizes and have different weight-bearing classes. To choose the best manhole cover for a project, you might start with matching the size to that of the manhole it will cover.

It’s also important to consider the application of the manhole cover. Certain pedestrian walkways may benefit from lightweight solutions such as polypropylene to minimise corrosion risk and maintain a safe flush surface. Galvanised steel is robust enough to handle areas of high foot traffic, making it ideal for driveways. Consult with our expert team if you have any questions on which manhole covers are best for safety and durability.

What Shapes Are Manhole Covers?

Round manhole covers are common on roads and motorways, as they’re robust enough for high-traffic areas that encounter constant vehicle movement. Whereas square drain covers are used in industrial and commercial areas as they’re easy to install in modular paving. Both types of manhole covers come in different sizes and provide essential functions in streets and commercial zones. It’s important to choose the right material to ensure compliance and prevent structural issues. You can also get a recessed cover, below are some key features and benefits.

Recessed Manhole Covers

Key Features:

- Designed for aesthetic integration

- Suitable for various paving and tiling materials

- Durable and weather-resistant

Benefits:

Recessed manhole covers are perfect for areas where appearance is important. They allow for the insertion of paving, tiles or other materials, ensuring that the manhole cover blends seamlessly with the surrounding surface. These covers provide excellent strength and load-bearing capacity while maintaining the aesthetic appeal of driveways, patios and landscaped areas.

Applications:

- Patios and driveways

- Landscaped gardens

- Pedestrian zones

What Extra Manhole Cover Fittings Do We Supply?

Gully Gratings

Key Features:

- Heavy-duty design for high-traffic areas

- Available in various sizes and load capacities

- Efficient water flow and debris protection

Benefits:

Our gully gratings are designed to prevent debris from entering drainage systems, ensuring smooth water flow and reducing the risk of blockages. Manufactured from durable materials, they can withstand heavy loads and harsh conditions. Their high-strength construction makes them suitable for areas that experience frequent vehicle or pedestrian traffic.

Applications:

- Roads and car parks

- Industrial estates

- Public pathways

Stop Tap Covers

Key Features:

- Easy access for maintenance

- Tamper-resistant design

- Durable materials for long-term use

Benefits:

Stop tap covers protect vital underground stop taps from damage and tampering. They ensure that taps are easily accessible for maintenance and adjustments while safeguarding them from environmental exposure. These covers are ideal for applications requiring frequent access.

Applications:

- Residential driveways

- Pavements and pedestrian zones

- Commercial properties

Lifting Keys

Key Features:

- Suitable for a variety of cover types

- Easy to use

Benefits:

Our lifting keys are designed for safe and efficient removal of manhole covers. Their ergonomic design ensures easy handling and reduces the effort required to access underground drainage systems. These tools are compatible with various types of covers, making them versatile and essential for maintenance crews.

Applications:

- Drainage system maintenance

- Local authority services

- Commercial drainage infrastructure

What Are The Considerations For Manhole Weight Classes?

Consider the types of traffic that will pass over your manhole cover and frame in general use, as this will determine the weight-bearing class you need. The lightest class is A15, which is suitable for gardens, patios and pedestrian only areas. Class B125 might be better for areas with light vehicle traffic, such as domestic driveways, whereas C250 will be used for more heavy commercial vehicles. Main roads and public car parks are likely to need D400 class manhole covers. The highest class of all, F900, is used for places that are likely to face extreme weight loads such as industrial areas, airports and docks.

Do Manhole Covers Need To Be Locked?

This will largely depend on the intended application. In situations where security and safety are a concern, it’s good to have a lock for your cover. This can prevent unauthorised entry and increase public safety. Consult with a member of our expert team at the time of ordering your manhole cover if you need further advice for your industry.

How Are Manhole Covers Constructed?

This will depend on the type of material. For ductile iron, molten metal is cast into moulds and treated for enhanced durability and flexibility to avoid cracking under pressure. This is essential for manhole covers to be able to withstand high-traffic zones.

The material used to manufacture manhole covers and frames will be limited by this weight class, with ductile iron used for the higher classes. Some weight load classes offer the option of recessed galvanised steel manhole covers. These are frequently used for domestic driveways and plazas, where the recessed cover contains paviours, a concrete screed, asphalt or resin-bound aggregate to match the surrounding surface.

Help & Advice

Related articles

Delivery options

Enter your postcode for delivery timescales, accurate stock levels, and your nearest depot